Get Reliable and Smooth Operations with Membrane Switch for Better Functionality

Discover the Versatile Use Membrane Switch in Modern Electronics

In the world of modern electronics, the application of membrane buttons is incredibly extensive, extending from smooth customer devices to critical clinical tools. As sectors proceed to progress, the assimilation of membrane switches in devices style is critical, encouraging not only to meet however exceed the extensive demands of both performance and visual allure.

Checking Out the Duty of Membrane Layer Switches in Customer Electronics

Why are membrane layer changes so common in consumer electronics? The answer exists in their one-of-a-kind combination of adaptability, dependability, and affordability. Membrane buttons are affordable to make, making them an attractive alternative for high-volume production common in consumer electronics. Their building and construction, including a thin, adaptable layer that can easily be incorporated right into numerous devices, enables for smooth, small item styles.

Moreover, these switches are known for their toughness and low upkeep. From microwave ovens to remote controls, membrane switches give a useful, straightforward interface that sustains the vibrant nature of consumer electronic devices.

Membrane Layer Changes in Medical Devices: Enhancing Interface

Membrane layer buttons also play a substantial function in the realm of medical devices, where they boost interface with their distinct advantages. These buttons are especially valued for their dependability and ease of sanitation, important in healthcare settings where cleanliness is vital. The smooth, closed surface area of membrane layer switches over enables for very easy disinfection, reducing the risk of contamination and spread of microorganisms. In addition, their style versatility fits the ergonomic and visual demands of medical equipment, making devices more instinctive and available for medical care professionals.

Membrane layer buttons likewise add to the durability of clinical gadgets. Their resistance to liquids and contaminants guarantees that vital tools stays functional in various scientific setups, consisting of surgeries where exposure to fluids these details prevails. This sturdiness, combined with responsive responses and inconspicuous style, makes membrane layer changes an important component in enhancing the performance and security of clinical tool interfaces.

The Influence of Membrane Activates Industrial Tools Style

In the realm of industrial equipment design, the incorporation of membrane layer switches has actually marked a considerable development. The slim account of membrane changes allows for even more small equipment designs, while their resistance to chemical, dirt, and water impurities makes them suitable for commercial settings.

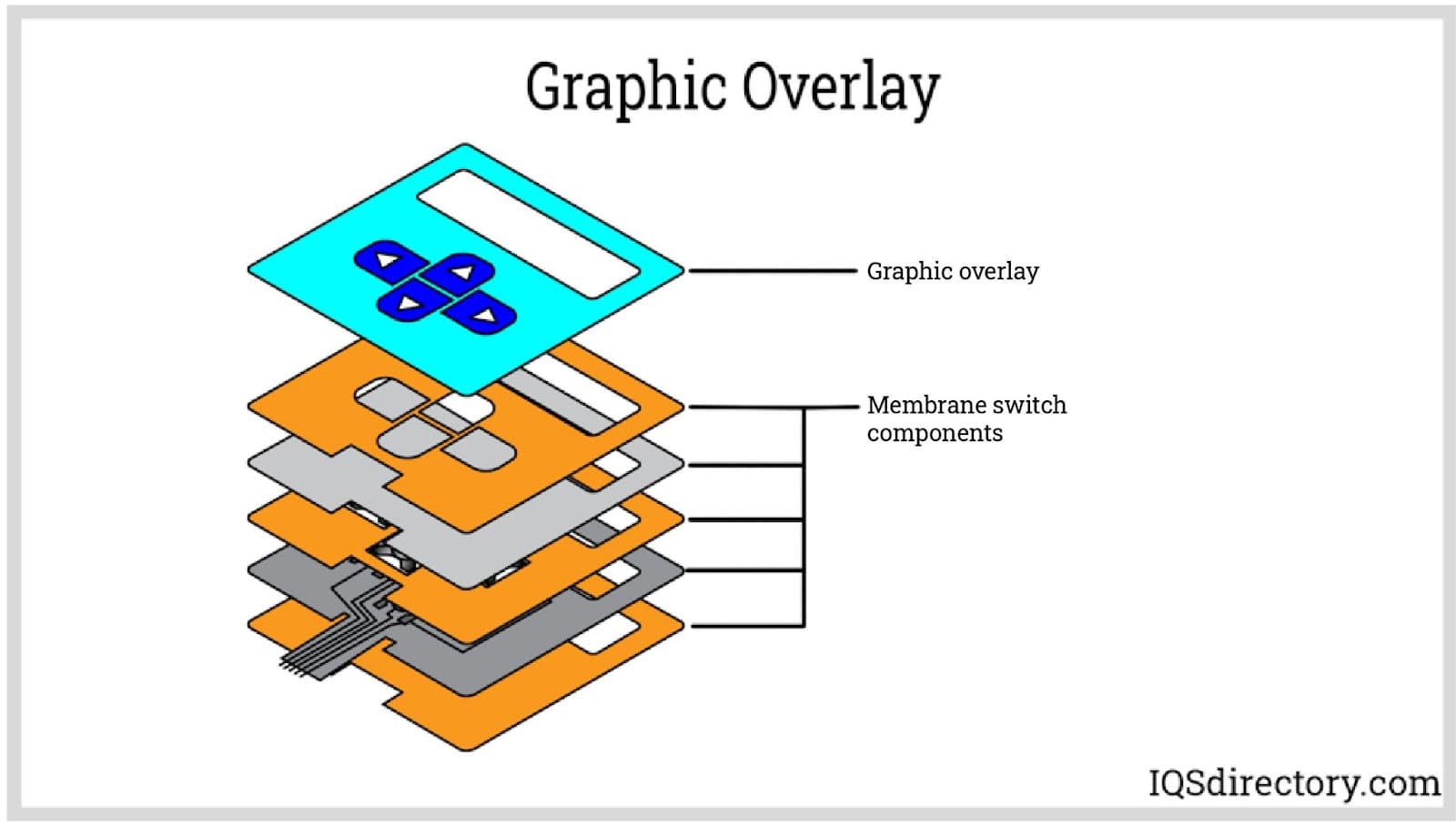

Moreover, the customizability of membrane layer switches over makes it possible for developers to integrate specific tactile comments and graphical overlays that boost the user experience and increase effectiveness. This assimilation sustains operators in attaining precision control over intricate machinery. The total effect is a substantial enhancement in the functionality, integrity, next page and user-friendliness of commercial devices, aligning with the raising demands for technological advancement and functional efficiency in modern industries.

Verdict

Membrane switches have revolutionized modern electronics, using sleek, sturdy, and adjustable user interfaces throughout various fields. This technology not only fulfills the requiring conditions of different areas yet also considerably enhances individual experience, making membrane switches a cornerstone of contemporary electronic style.

In the world of contemporary electronics, the application of membrane layer switches is incredibly considerable, spanning from sleek consumer devices to critical medical devices.Why are membrane switches so common in consumer electronics? Membrane switches are economical to produce, making them an eye-catching option for high-volume manufacturing typical in customer electronic devices. From microwave ovens to remote controls, membrane buttons provide a practical, additional resources user-friendly interface that supports the vibrant nature of customer electronic devices.